Compressed-air cylinders quietly turn pressurized air into strong, straight-line pushes that factories depend on. Even so, how you bolt the tube to its frame can make or break the whole job. Pick the wrong mount and alignment drifts, force piles in the wrong spot, wear doubles, and the system lives half as long.

This post talks directly to the engineers and designers who want their cylinders running true, safe, and tough. If you build robots, package goods, move pallets, or dream up one-off machines, knowing the different pneumatic cylinder mounting types is step one before you order automation parts.

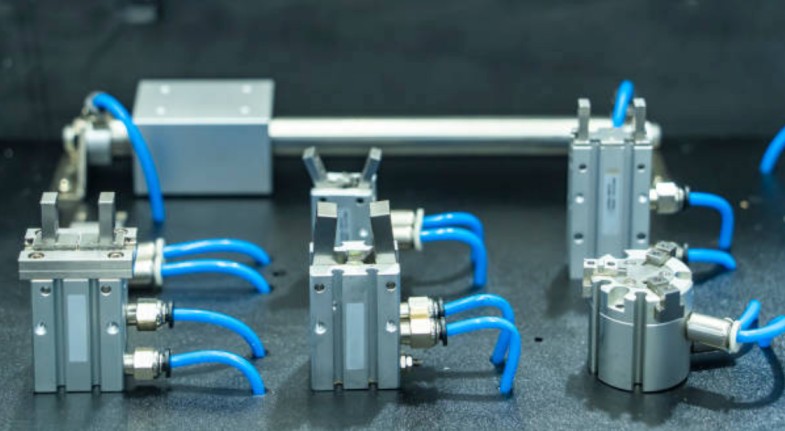

Why Cylinder Mounting Types Matter in Industrial Applications

Picking the right way to attach a cylinder isn’t something you bulleted once and walked away from. The mount soaks up shock, helps keep things lined up, and slowly decides how much wear everything will take. A bad choice or a simple twist out of line can chew up parts, suck away efficiency, and halt production before anybody planned for it.

Get it right, though, and the piston rod stays straight, incoming hits get cushioned, moving forces act where you hoped, and swapping out a worn piece turns into a 20-minute job instead of a weekend bust.

That’s why, when teams push the button on new pneumatics, they do themselves a favor by digging into the mounting tricks first, long before a single screw is turned.

Flange Mounting: Rigid and Direct Force Transfer

Flange mounts show up in jobs where a cylinder is expected to behave like it grew into the steel frame. Front flanges and rear flanges bolt straight to the surface, locking the actuator in place.

Because that outer face is locked down, every ounce of force sneaks right along the piston stroke, a feature that press rooms, hoists, and heavy-duty pulls tend to love.

Flange mounts are reliable, yet they won’t forgive side forces or minor twists. That reality puts the burden on designers to create perfectly straight support rails. For rigid-frame machinery that faces heavy push-and-pull loads, a flange mount is usually the first choice.

Foot Mounting: Built for Horizontal Duty

A foot-mounted pneumatic cylinder sits flat against a base plate and stays put, making it great for conveyor decks, sliding tables, and busy assembly jigs. The profile stays low, but the setup only performs well if everything lines up exactly.

Factory teams often skip the fuss of extra brackets, even though uneven forces can bend the rod if no guides are added. Because the design is simple, foot mounts fly off warehouse shelves and get installed in minutes. That fast swap is why so many technicians head online to buy automation parts once the job needs a reliable, trouble-free option.

Clevis and Trunnion Mounting: Smooth, Swinging Action

When machines need to twist or swing, you really can’t beat a clevis or trunnion mount. A clevis mount pins to one end of the cylinder, letting it pivot freely as the piston extends or retracts. The trunnion style is a little different: it locks trunnion pins right to the cylinder wall so the whole assembly can roll around a horizontal axis.

Both setups shine on hinged arms, tilting platforms, and press tools that don’t stop changing angles. They soak up side loads and keep wear in check, which is why you’ll find them in high-cycle equipment that runs, literally, nonstop.

If you’re eyeballing pneumatic cylinder mounting styles for jobs that spin or swerve, these pivoting options hand you the flexibility you need without the frame twisting apart. It’s a big deal when you’re about to order automation parts for a machine that moves in every direction.

Rear and Front Cap Mounting: Slim, Centered Space

Cramped spaces force designers to get clever, and rear or front cap mounts are one of the smartest tricks in the book. By bolting the cylinder at its end plates instead of along the barrel, the setup shrinks the footprint and spreads axial forces evenly. Every inch counts, and this style basically whispers, Mount me anywhere.

Rear and Front Cap Mounts: Space-saving Strength

Rear and front cap mounts show up all over the place, from cramped assembly lines to robotic inspection rigs. By lining everything up axially, they make sure force follows the stroke path, so wear drops and movements stay sharp.

Because they hug the ends of the cylinder, automation engineers love these mounts in tight hatches where every inch counts. You get rock-solid support without stealing room you probably don’t have anyway.

Intermediate and Tie-Rod Mounting: Heavy-Duty Flexibility

Intermediate mounting holds a different trick. It fastens the cylinder along its tie rods, letting builders pick exactly where support lands.

That freedom shines in long-stroke setups, whether it’s an automotive press or a crane hauling bulky material. When the actuator needs to be both tall and stable, this style steps up.

Engineers planning custom machines lean on the adjustability because it means fewer compromises. If you’re about to buy automation parts, don’t skip the tie-rod option; it might be the piece that finally clicks into place.

Choosing the Right Mounting for Your System

Picking the right cylinder mount is about more than lining up bolt holes. You have to think about how the machine will move, how much weight it will carry, and whether you can even reach the mounting point when something breaks.

Try answering these quick questions: Will your cylinder stay put or travel with the load? Does the application call for a straight pull, a pivot, or some weird diagonal path?

How tight is the space around the mount? Will the cylinder slam in and out at high speed, or will it just creep along under a heavy load? And, be honest, how often do you really want to swap the cylinder in and out?

The way you answer those questions points you toward a specific kind of bracket, yoke, or clevis. Because the market is flooded with hardware, you may as well choose a vendor that stands behind the stuff they sell.

A good supplier can hand you a pre-packaged mount kit, a set of 2D drawings, and a set of torque specs so you waste zero time guessing what size wrench to grab. That kind of support turns what used to be trial-and-error into something almost predictable.

Conclusion

Pneumatic cylinders do their best work when they’re held the right way. Match the mounting type to the task, and you’ll notice smoother movements today and fewer headaches tomorrow. Long life and reliable automation often come down to that one smart choice.

Engineers and designers who work in B2B know that a little homework up front can translate into big savings later. When they finally click buy automation parts, knowing how different mounting styles tweak performance lets them ship smoother, tighter, and larger-scale systems.