Across the aerospace, automotive, medical technology, and industrial automation fields, the continuous demand for multifaceted, high-performing parts and components is escalating. One of the most efficient and adaptable techniques for manufacturing intricate parts is turning, specifically CNC turning. This process refinement “when executed with exceptional accuracy,” as stated in the excerpt allows manufacturers to achieve tight tolerances, to enhance multifaceted performance, reliability and prolong component life.

For manufacturers in a B2B setting, engaging proficient precision parts machining manufacturers is critical to guarantee that CNC turning not only produces the CNC turned parts but proceeds to shape the components with the precision that mission-critical applications demand. These articles delve into the specifics of CNC turning as a solution for complex geometry creation, the importance of tight tolerances, and elaborate on the relation of the tolerances to product performance reliability.

CNC Turning and its modern manufacturing significance.

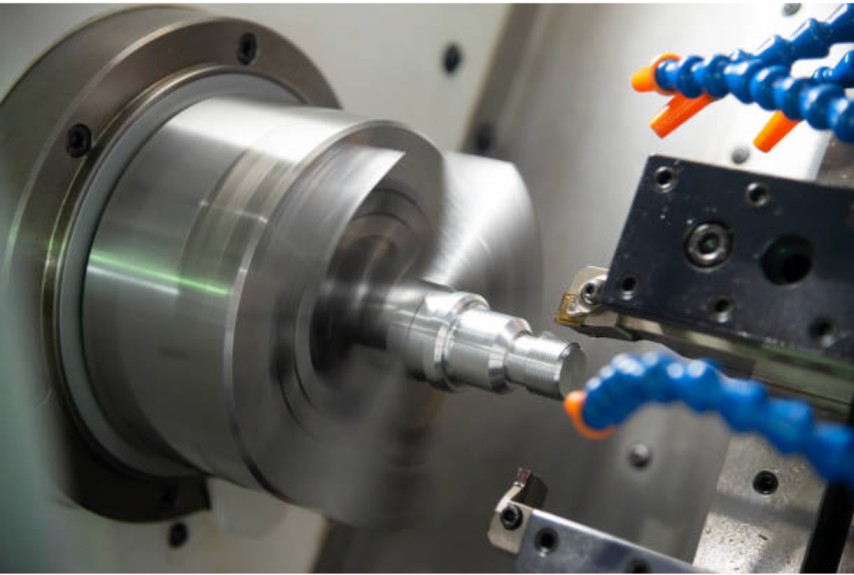

CNC turning is a subtractive process of manufacturing that employs a cutting tool to shape a workpiece as it rotates. Turning is distinct from milling as it uses a rotating part rather than stationary parts.This technique has notable efficiency for making cylindrical, conical, or spherical parts. For CNC turning in the B2B sector, some examples of products made are:

- Components for hydraulic systems

- Precision-machined shafts and spindles

- Couplings and threaded connectors

- Fasteners of high performance

- Housings and sleeves of complex geometry

With high-precision machinery and skilled technicians together with sophisticated software, CNC turning makes it possible to manufacture parts with detailed shapes and tolerances of ±0.001mm.

Performance and Reliability – Why the Tighter, the Better

Tighter tolerances are crucial in some industries where there is no room for mechanical failure. In this case, precision is more than a goal, it becomes a necessity. Close tolerances ensure:

- Exchangeable – All components are perfectly fitting and assembled without any modifications.

- Wear Reduction – Components perfectly aligned in position experience lower friction, increasing lifespan.

- Reliable Consistent Performance – All operations and components are guaranteed uniform functions regardless of time.

- Enhanced Safety – Malfunctioning is less likely to happen due to the absence of dimensional variations.

Let’s take the aerospace industry, where precision is critical. A few millimeters change can alter aerodynamic efficiency or introduce mechanical stress. Likewise, consider medical devices; precision not only enhances performance but also preserves the patient’s safety.

Competencies in CNC Turning for Advanced Shape Manufacturing

CNC turning technology enables the production of contours which are complex in nature and would be extremely challenging to produce manually. Using multi-axis CNC turning centers, precision parts machining manufacturers are able to perform several operations in one set, which include:

- Internal and External Grooving – Crafting complex channels for seals, rings, or lubrication for advanced part functionalities.

- Tapered Profiles – Smooth progression in diameter suitable for many industrial parts.

- Thread Cutting – Threads produced are accurate for precise mechanical and fluid joints.

- Contour Turning – Smooth curves and complex shapes are easy to create and are referred to as irregular profiles.

- Boring and Drilling – Precise internal cavities are produced with advanced accuracy in a single set.

Including these operations increases productivity, machining consistency, decreases the amount of material that needs to be handled, as well as accuracy from re-clamping errors.

Improving Reliability through Advanced Material Choices and Surface Finishes

CNC turning can adapt to various materials, using engineered plastics or alloys, as well as aluminum which is lightweight. The type of material a business uses will directly impact their performance and CNC turning will be suitable for:

- Stainless Steel – Harsh environments demand stress and corrosion resistance which these metals provide.

- Titanium – Aerostream and medical parts rely on aviation grade metals as they are lightweight and biocompatible.

- Brass and Copper Alloys – Known for their electrical conductivity and ease of machining.

- Engineering Plastics – Appropriate for lightweight and non-conductive applications.

Besides choosing the right materials, surface treatments are equally important to the performance of the component. CNC turning allows for the achievement of surface finishes from functional roughness, which aids mechanical gripping to smooth finishes, which reduces friction. Further polishing and anodizing or coating the component improves wear resistance and corrosion resistance.

Quality Control and Inspection in CNC Turning

Advanced machines alone are not sufficient to ensure complex components are manufactured to tight tolerances. Stringent quality control is also needed. Leading precision parts machining manufacturers incorporate parts inspection in every phase of production and utilize the following systems:

- Coordinate Measuring Machines (CMM) – 3D measurement of complex shapes.

- Laser Scanning Systems – Non-contact, rapid surface inspection.

- Roundness and Surface Profilometers – Check important rotational accuracy and surface finish.

- In Process Monitoring Sensors – Identify changes that could lead to defects.

With this systematic approach, manufacturers are able to ensure that their parts are all produced within the given tolerances, thereby reducing scrap rates and improving delivery reliability for their B2B clients.

Advantages for B2B Suppliers

In the case of complex parts for which businesses have to source intricate components, the benefits of CNC turning coupled with tight tolerance machining are numerous:

- Prototyping and Production Speed – With multi-axis turning centers, functional prototypes and production runs can be accomplished in far less time.

- Cost Savings – Discounted rework and scrap means time and resources can be saved.

- Flexibility in Design – Greater innovation in products can be achieved due to complex geometries.

- Uniform Quality Over High Volumes – High repeatability translates to consistent quality, even in mass production.

Meeting tight tolerances boosts confidence in products’ long-term performance consistent with automation, bolstering supplier partnerships and brand image, which in turn enhances reputation.

Concluding Remarks

For complex geometries, robust performance, and exacting dependability, CNC turning along with tight tolerance specialization stand as an unbeatable advantage. Their strategic importance as precision parts machining manufacturers in the aerospace sector and in the production of precision instruments for the medical sector is unparalleled.

Investment in sophisticated CNC machinery, along with top engineering talent and strict quality inspection measures, enables these manufacturers to assist B2B customers in greatly advancing the limits of component design and production. In this industry, precision is a critical factor, and being able to provide it on demand to customers is not an advantage, but a condition for success.